Cargo Lashing System

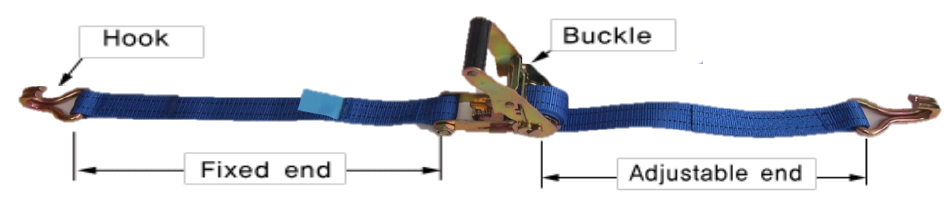

Cargo Tie-down is composed with Buckle, Strap and end fittings. The end fittings are optional according to specific requirement. It is widely used in transportation such as tow truck self-saving, cargo binding, cargo lashing and binding. Cargo Tie-down is widely used in all kinds of field with its advantages.

Cargo Tiedown System (Stitched Lashing)

Cargo Tiedown System (Stitched Lashing)

- Various colors and widths are available

- Guarantees easy use by automatic length adjustment and click-type buckle

- Reduces freight damage

- Product damage may be prevented through the use of appropriate lash as per type

- Offers customized printing

◆ 1”(25mm) Cargo Tiedown System

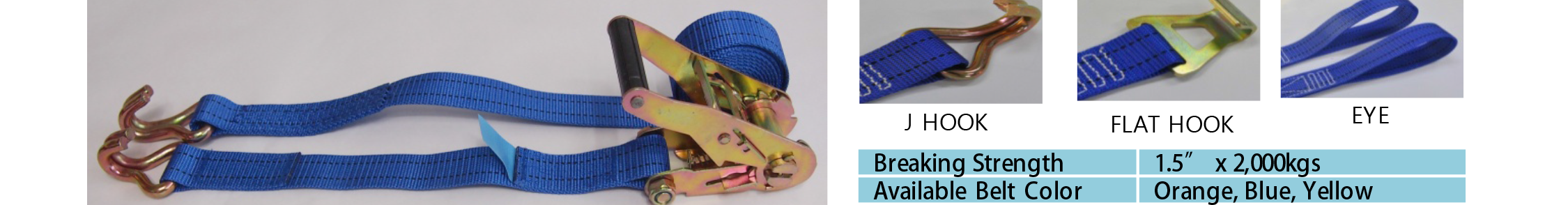

◆ 1.5”(35mm) Cargo Tiedown System

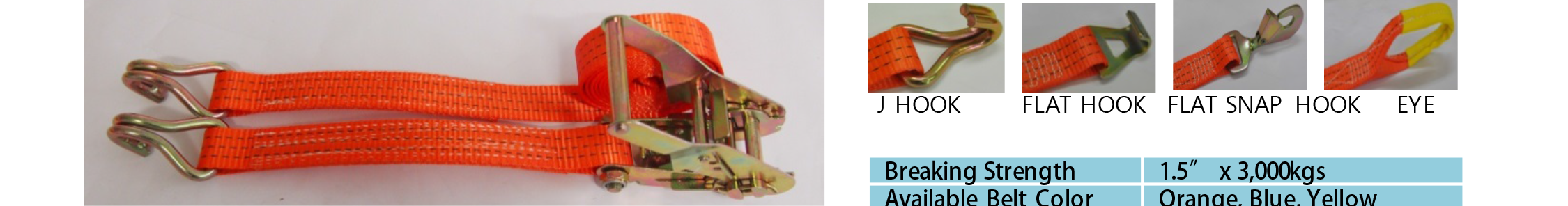

◆ 1.5”(35mm) Cargo Tiedown System

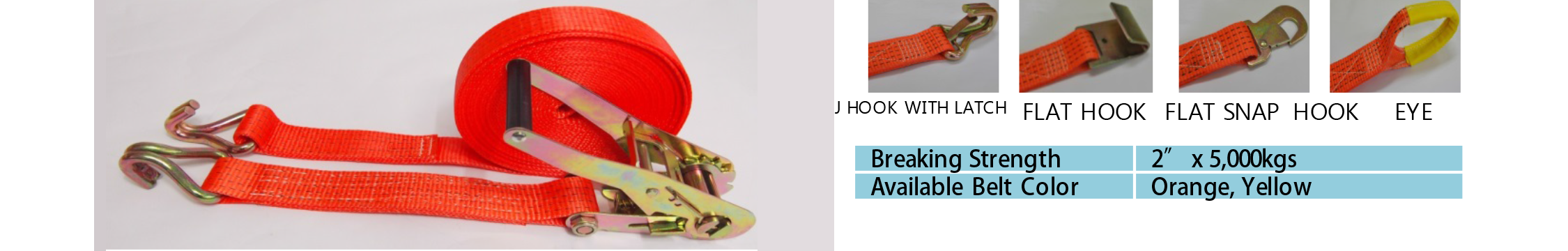

◆ 2"(50mm) cargo tiedown System

◆ 3”(75mm) Cargo Tiedown System

◆ 4”(100mm) Cargo Tiedown System

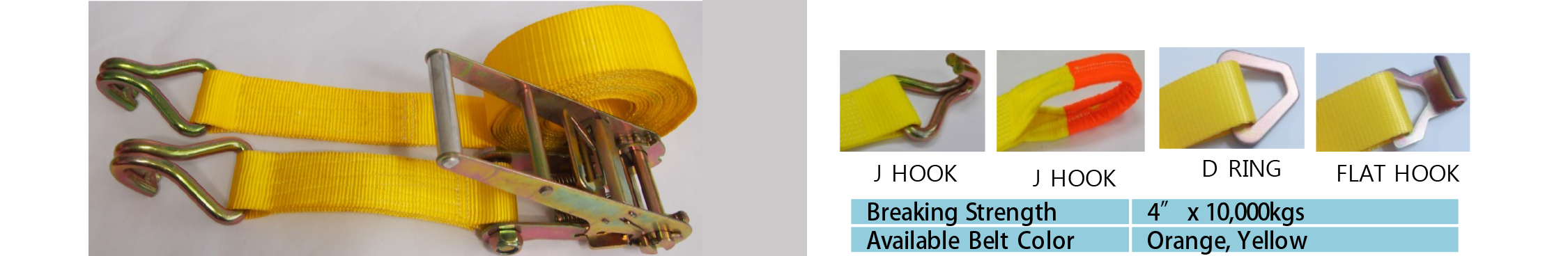

2 bolt Ratchet Lashing System (Non-Stitched Lashing) (Japan patent)

2 bolt Ratchet Lashing System (Non-Stitched Lashing) (Japan patent)

◆ Advantage of 2 Bolt Ratchet Lashing System

- The Ratchet Bolt of existing lashing is sewed on with webbing. Please consider the size of the object being fixed before purchasing the product.

- Existing sewed-on products cannot be length-adjusted. The 2 Bolt method is not sewed on, allowing for easy length adjustment.

- Wide ranging belt sizes: 50MM, 40MM, etc.

- Economical as the rachet, hook, buckle and belt are purchasable separately. The product allows for flexible response to various situations and needs.

- Reusable and widely used in packaging. Reduces cost by containing various types of cargo.

◆ Compose of 2 Bolt Ratchet Lashing System

- 2 Bolt Ratchet : 1pc (Japan Patent : 2009-001527)

- 40mm & 50mm Lashing Webbing

- Welded J hook : 2pcs

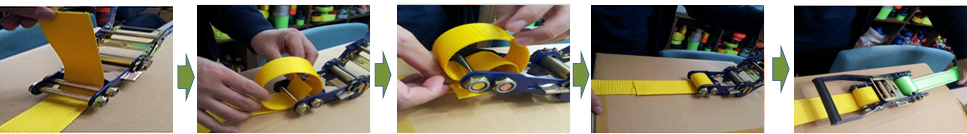

◆ How to use Lashing Webbing with 2 Bolt Ratchet Buckle-Non Stitched Lashing

◆ How to use Lashing Webbing with Buckle

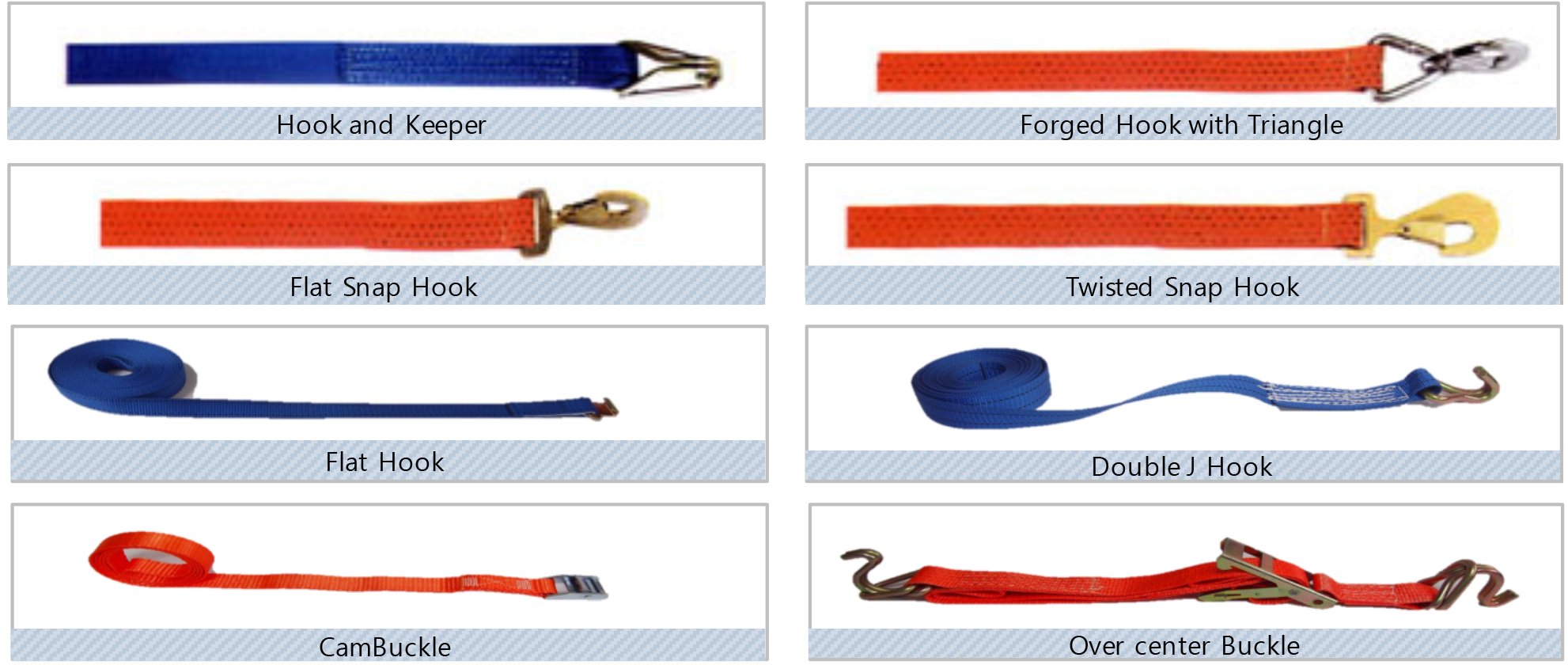

End Fitting Cargo Tiedown System

End Fitting Cargo Tiedown System

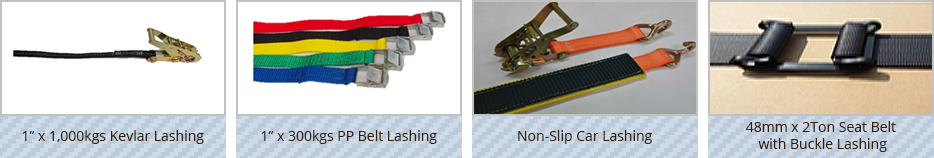

Various Belt Lashing

Various Belt Lashing

Actual examples of Lashing in use

Actual examples of Lashing in use